Arla Foods Ingredients, a Denmark-based subsidiary of the global dairy cooperative Arla Foods, unveiled a revolutionary “no acid whey” dairy production concept in Wisconsin, USA. Using its proprietary Nutrilac® HighYield milk proteins, the innovation promises 100% milk yield with zero waste, reduced equipment needs, and improved cost-efficiency. This sustainable development is designed to eliminate acid whey — a by-product that has long burdened strained dairy product manufacturing — offering an environmentally friendly, high-protein solution for dairy producers.

Arla Foods Ingredients, a subsidiary of the Danish multinational dairy cooperative Arla Foods, has introduced a new dairy production concept in the United States that promises to eliminate waste in the production of strained dairy products.

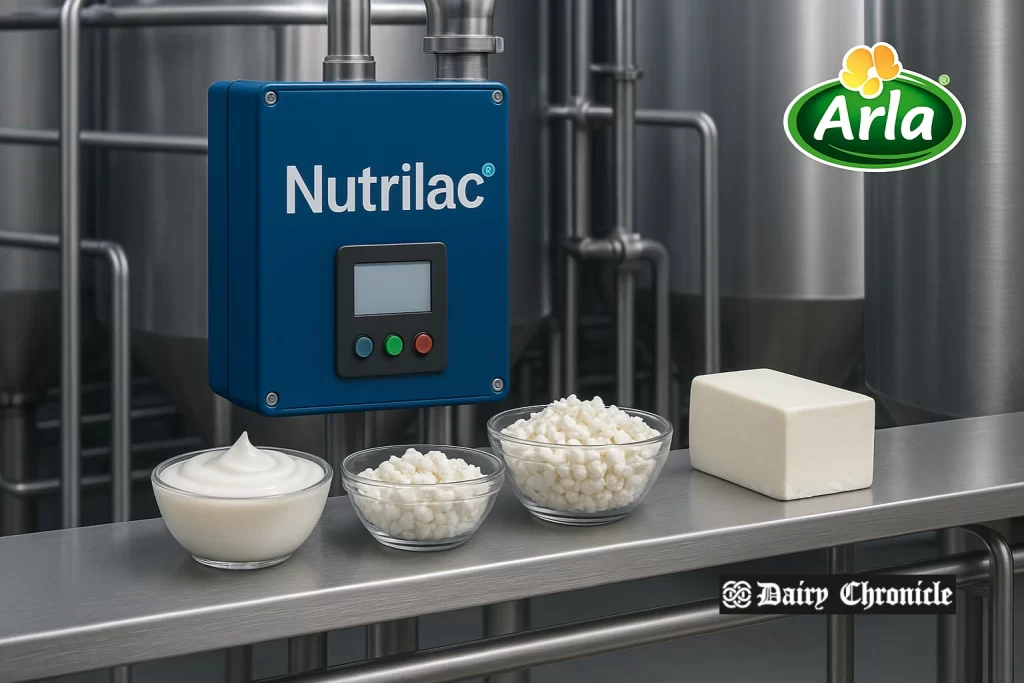

Launched in Wisconsin, a key state in America’s dairy belt, the innovation centers around Nutrilac® HighYield milk proteins. This proprietary protein solution enables dairy producers to achieve a 100% milk yield by removing the acid whey by-product from the manufacturing process of Greek-style yoghurts, cottage cheese, and cream cheese.

Acid whey, which traditionally accounts for up to two-thirds of discarded milk during production, has long presented a disposal challenge and environmental concern. With Nutrilac® HighYield, dairies can bypass filtration steps where acid whey is normally separated, allowing more efficient production with fewer equipment requirements.

“Now, instead of managing the waste, we’re eliminating it altogether,” said Claus Bukbjerg Andersen, Senior Category Manager at Arla Foods Ingredients. “It’s a win for producers and for sustainability.”

The launch showcases four dairy product formats made possible by the technology — including creamy Greek-style yogurt, two varieties of high-protein cottage cheese (7.4% and 10%), and a spreadable cream cheese ideal for cooking.

The solution aligns with industry trends favoring clean-label, protein-rich products while supporting environmental goals through reduced waste, carbon emissions, and water usage.

As food producers across the globe face growing climate and cost pressures, Arla’s no-waste approach signals a shift toward more sustainable and responsible dairy production — potentially setting a new benchmark for the industry.